T

his project involves the design and fabrication of ASME Vessels, Atmospheric Pressure Storage Tanks, and associated structures for a client specializing in the oil & gas and chemical plant tanks. The company operates in the United States and is committed to ensuring that every mechanical device adheres to ASME Section VIII Div. 1 specifications. Structural and plumbing materials must meet relevant ASTM standards, and all access platforms and ladders must comply with OSHA standards.

_____________________

Challenges

Project Overview:

• Client in the ASME Vessel, Atmospheric Pressure Storage Tank (Oil & Gas, Chemical Plant Tanks Form Area) design and fabrication company, having facilities in United States.

• Every mechanical device must adhere to the relevant ASME Section VIII Div. 1 specifications.

• All structural and plumbing materials must adhere to the relevant ASTM standards.

• OSHA standards must be followed in the design and construction of all access platforms and ladders.

• Client in the ASME Vessel, Atmospheric Pressure Storage Tank (Oil & Gas, Chemical Plant Tanks Form Area) design and fabrication company, having facilities in United States.

• Every mechanical device must adhere to the relevant ASME Section VIII Div. 1 specifications.

• All structural and plumbing materials must adhere to the relevant ASTM standards.

• OSHA standards must be followed in the design and construction of all access platforms and ladders.

_____________________

Approach

Project Scope:

• ASME Vessel with Internal tray design, Internal Baffles Design, Access Platforms and Ladders Design (3d Model).

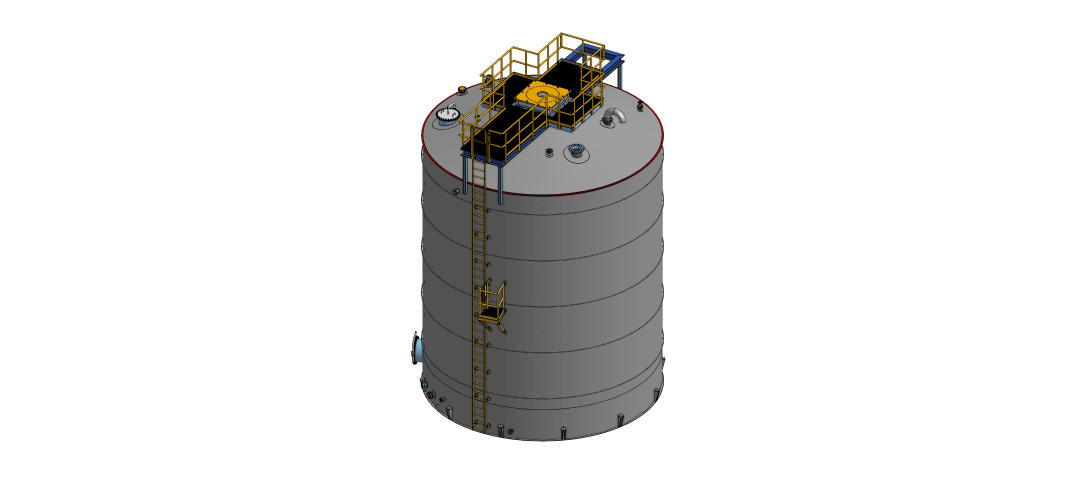

• Storage Tank with Agitator Design (3d Model).

• ASME Vessel Detail Engineering.

• Storage Tank with Spiral Stairs and access Platforms design, Ladders Detail Engineering as per OSHA Standards.

• A complete set of 3D Model and fabrication drawings developed in ONSHAPE cloud-based server within the agreed project schedule.

Project #1

• DESIGN CODE - API 650

• TOTAL VOLUME - 137,047 GAL.

• SHELL/HEAD – CYLINDRICAL/ CONICAL

• DESIGN TEMPERATURE - 190 °F

• CONTENTS – CHEMICAL SOLUTION

Project #2

• DESIGN CODE - API 650

• TOTAL VOLUME – 34,158 GAL.

• SHELL/ HEAD – CYLINDRICAL/ CONICAL

• DESIGN TEMPERATURE – 91.4 °F

• CONTENTS - STERILIZED PRODUCT SOLUTION

Project #3

• DESIGN CODE - API 650

• TOTAL VOLUME – 260209.5 GAL.

• SHELL/ HEAD – CYLINDRICAL/ CONICAL

• DESIGN TEMPERATURE – 250 °F

• CONTENTS – VINYL ACETATE SOLUTION

• ASME Vessel with Internal tray design, Internal Baffles Design, Access Platforms and Ladders Design (3d Model).

• Storage Tank with Agitator Design (3d Model).

• ASME Vessel Detail Engineering.

• Storage Tank with Spiral Stairs and access Platforms design, Ladders Detail Engineering as per OSHA Standards.

• A complete set of 3D Model and fabrication drawings developed in ONSHAPE cloud-based server within the agreed project schedule.

Project #1

• DESIGN CODE - API 650

• TOTAL VOLUME - 137,047 GAL.

• SHELL/HEAD – CYLINDRICAL/ CONICAL

• DESIGN TEMPERATURE - 190 °F

• CONTENTS – CHEMICAL SOLUTION

Project #2

• DESIGN CODE - API 650

• TOTAL VOLUME – 34,158 GAL.

• SHELL/ HEAD – CYLINDRICAL/ CONICAL

• DESIGN TEMPERATURE – 91.4 °F

• CONTENTS - STERILIZED PRODUCT SOLUTION

Project #3

• DESIGN CODE - API 650

• TOTAL VOLUME – 260209.5 GAL.

• SHELL/ HEAD – CYLINDRICAL/ CONICAL

• DESIGN TEMPERATURE – 250 °F

• CONTENTS – VINYL ACETATE SOLUTION

_____________________

Conclusion

In conclusion, this project signifies a commitment to meeting stringent industry standards, including ASME specifications, ASTM standards, and OSHA regulations. The design and engineering process, detailed for ASME vessels, storage tanks, and associated structures, adheres to the highest quality and safety standards. The API 650 design codes and project-specific details highlight the diversity of applications, from chemical solutions to sterilized product solutions. This comprehensive approach ensures the successful development of reliable, compliant, and efficient equipment for the client's oil & gas and chemical plant operations in the United States.

_____________________