T

his project involves the design and fabrication of process skids for a client specializing in this field, with facilities located in the United States. The client emphasizes strict adherence to industry standards, ensuring that all process piping follows applicable ASME B 31.3 specifications. Furthermore, all mechanical equipment is designed in accordance with relevant ASME standards, and materials used in piping construction meet applicable ASTM standards.

_____________________

Challenges

Project Overview:

• Client in the Process Skid design and fabrication company, having facilities in United States.

• All process piping accordance with applicable ASME B 31.3.

• All mechanical equipment shall be in accordance with applicable ASME standards.

• All materials used in piping construction shall meet applicable ASTM standards.

• Client in the Process Skid design and fabrication company, having facilities in United States.

• All process piping accordance with applicable ASME B 31.3.

• All mechanical equipment shall be in accordance with applicable ASME standards.

• All materials used in piping construction shall meet applicable ASTM standards.

_____________________

Approach

Project Scope:

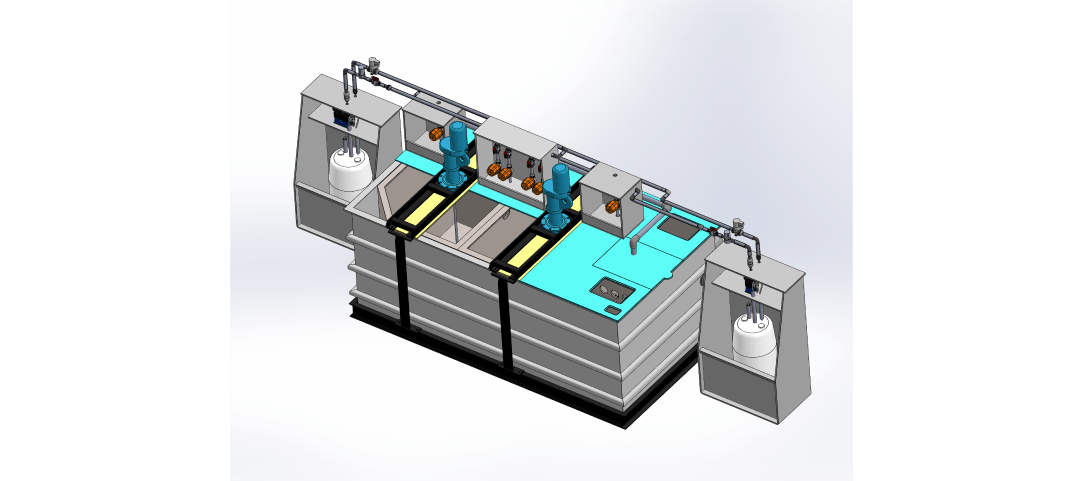

• Process Skid Layout Design (3d Model)

• Process Skid Detail Engineering

• A complete set of design & detail engineering 3D Model and fabrication drawings developed in SOLIDWORKS within the agreed project schedule.

Codes & Standards:

• ASME B31.3

• ASTM

• AISC

• Process Skid Layout Design (3d Model)

• Process Skid Detail Engineering

• A complete set of design & detail engineering 3D Model and fabrication drawings developed in SOLIDWORKS within the agreed project schedule.

Codes & Standards:

• ASME B31.3

• ASTM

• AISC

_____________________

Conclusion

In conclusion, this project exemplifies a commitment to excellence in the design and fabrication of process skids. Adherence to ASME B31.3, ASME, ASTM, and AISC standards guarantees that the resulting product meets the highest industry specifications. The utilization of SOLIDWORKS for 3D modeling and fabrication drawings underscores a dedication to precision and efficiency. Through this approach, the client can expect a top-tier process skid tailored to their specific requirements, contributing to the success of their operations in the United States.

_____________________